Our Systems

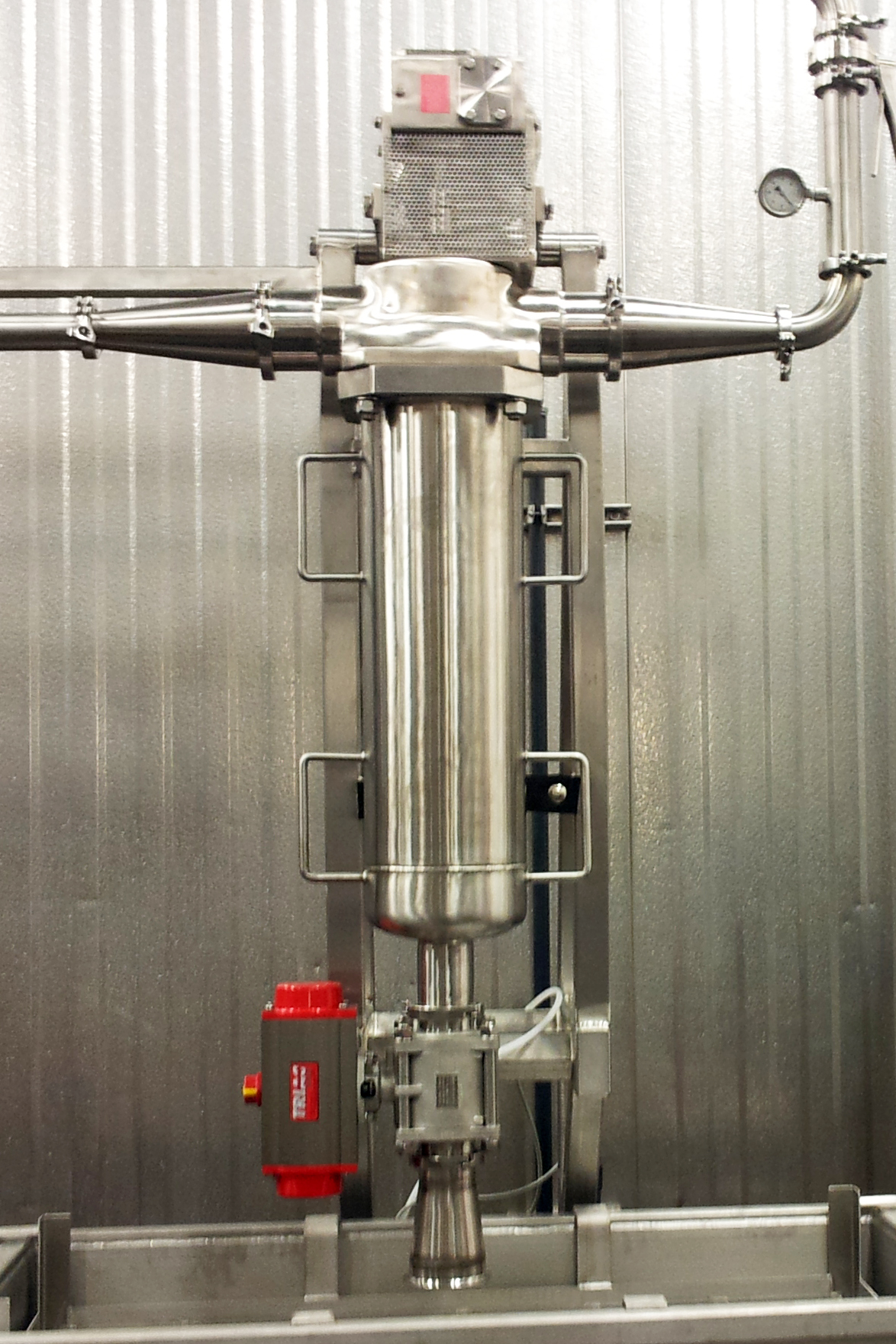

The Spencer Strainer System is a self-cleaning filter-strainer system that is unique in its design and effectiveness. How does it achieve the desired results your process needs?

Product to be filtered enters the strainer through the inlet; filtration is from the outside in.

After the particles are screened out of the flow, the product exits up through the center to the outlet.

The particles accumulate in the canister and are purged as needed.

The purged particles are piped away for disposal, recycling or re-use.

There are no bags or elements to be replaced.

The process is sealed, keeping products in the piping and out of the atmosphere.

The process is continuous, avoiding stoppages and waste found in other types of filtration.

Screens of various micron size openings can be easily interchanged for multiple applications.

All strainers are suitable for aseptic applications.

Our strainers also work well as pre-filters upstream of membranes, centrifuges, and other fine filter media.

DOWNLOAD OUR FULL CATALOG

Tell us more about your application data for a quotation.

The Spencer Strainer System is used in many applications including chemicals, coatings, brewing, ice cream, fried foods, peanut butter and toothpaste.